Enhanced thermal design is all about making things cooler, and that’s crucial in lots of applications. From electronics to vehicles, efficient heat management is key to performance and longevity. This deep dive explores the methods, materials, and design considerations for achieving top-notch thermal performance. We’ll look at everything from innovative heat sinks to the use of advanced materials and computational modeling.

The importance of effectively managing heat in various applications is highlighted, and the various techniques, materials, and optimization strategies are examined to demonstrate how they enhance thermal performance.

Materials and Components in Enhanced Thermal Design

Choosing the right materials and components is crucial for effective thermal management. Different materials exhibit varying thermal properties, impacting heat dissipation and overall system performance. Understanding these properties and selection criteria allows engineers to optimize designs for efficient heat transfer and reliable operation.A well-designed thermal system must account for the specific operating conditions and environmental factors, selecting materials that can withstand temperature fluctuations, stress, and potential chemical reactions.

This involves considering factors such as thermal conductivity, specific heat capacity, and thermal expansion coefficient.

Various Materials Used, Enhanced thermal design

A wide array of materials are employed in enhanced thermal design, each with unique thermal characteristics. Metals, ceramics, polymers, and composites are commonly used due to their diverse properties. The selection of a material is often driven by the specific application and desired performance characteristics.

Thermal Properties of Different Materials

Understanding the thermal properties of various materials is essential for effective thermal design. Thermal conductivity quantifies a material’s ability to conduct heat. Materials with high thermal conductivity facilitate rapid heat transfer, while low thermal conductivity materials are used for insulation. Specific heat capacity measures the amount of heat required to raise the temperature of a unit mass by one degree.

Thermal expansion coefficient indicates how much a material expands or contracts with temperature changes.

Selection Criteria for Materials

Several criteria guide the selection of materials in thermal design. These criteria include thermal conductivity, cost, availability, compatibility with other components, and the desired service temperature range. Consideration of the material’s mechanical properties, such as strength and stiffness, is also important in certain applications.

Comparison of Thermal Interface Materials

Thermal interface materials (TIMs) are crucial in transferring heat between components. Their performance is often characterized by their thermal resistance, which is inversely proportional to their thermal conductivity. Various TIMs, including thermal greases, thermal pads, and films, offer different thermal performance and application suitability. The selection of a TIM depends on factors such as the desired thermal resistance, operating temperature range, and the surface characteristics of the components.

Thermal Conductivity Table

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Copper | 400 |

| Aluminum | 237 |

| Steel | 50 |

| Silicon Carbide | 150 |

| Epoxy | 0.3 |

This table provides a general comparison of thermal conductivity for common materials. Note that values can vary based on specific formulations and processing methods.

Role of Advanced Composites in Thermal Management

Advanced composites offer significant advantages in thermal management. Their layered structures can combine high thermal conductivity with low weight or other desirable properties. For example, carbon fiber reinforced polymers (CFRP) are used in high-performance applications requiring both high strength and excellent thermal conductivity. Advanced composites can be tailored to specific applications by adjusting the composition and structure of the material.

Their ability to provide high thermal conductivity while maintaining lightweight characteristics makes them an attractive choice in aerospace and electronics applications.

Design Considerations and Optimization Strategies

Effective thermal design goes beyond simply dissipating heat; it’s about strategically managing heat transfer throughout a system’s components. Careful consideration of materials, component placement, and airflow is crucial for achieving optimal performance and reliability. This involves understanding how various factors influence thermal behavior and implementing solutions to maintain acceptable temperatures.

Key Design Considerations

Several critical aspects must be addressed during the design phase. These include the thermal properties of materials used, the geometry of components, and the system’s overall architecture. Proper material selection is paramount, considering factors like thermal conductivity, specific heat, and coefficient of thermal expansion. Geometric considerations, such as surface area and component spacing, directly impact heat dissipation.

The system’s architecture influences airflow patterns and the effectiveness of cooling solutions.

Optimization Strategies for Enhanced Thermal Performance

Optimization strategies are essential for achieving the desired thermal performance. One such strategy involves optimizing the airflow path to enhance convective heat transfer. This can involve modifying component placement or incorporating strategically placed fans or heat sinks. Another strategy focuses on improving radiative heat transfer. This can be achieved by using materials with high emissivity or by increasing the surface area exposed to the environment.

Conduction pathways can be minimized to reduce thermal resistance, often achieved through efficient heat spreader designs or by employing thermal interface materials.

Importance of Thermal Modeling in Design

Thermal modeling plays a crucial role in the design process. It allows engineers to simulate and predict the thermal behavior of a system under various operating conditions. This enables early identification and resolution of potential thermal issues before physical prototypes are built. Advanced computational fluid dynamics (CFD) simulations, for example, can model airflow patterns and heat transfer in complex systems, leading to significant design improvements.

This modeling process is particularly valuable in the design of electronic devices, where precise thermal management is critical to prevent overheating and component failure. Thermal simulations can be used to model different operating conditions, such as high-load scenarios or extreme temperatures, to ensure reliable performance under various stresses.

Thermal Management Solutions for Different Components

Effective thermal management solutions are tailored to the specific components and their operating environments. For example, high-power electronic components often benefit from liquid cooling systems, which can efficiently extract heat away from the device. Heat sinks, with their large surface area, are widely used to enhance convective heat transfer for electronic components. For applications requiring passive cooling, natural convection cooling or radiation cooling can be implemented.

In applications where space is limited, phase change materials (PCMs) can absorb and release heat as temperatures change, providing a thermal buffering effect.

Impact of Design Parameters on Thermal Performance

The impact of design parameters on thermal performance is profound. For instance, increasing the surface area of a heat sink can enhance heat dissipation by increasing the area available for convective heat transfer. Similarly, optimizing airflow patterns around components can improve convective cooling. Reducing the thermal resistance between components can improve the overall heat transfer. Proper selection of materials with high thermal conductivity is crucial in reducing thermal resistance within the component and through the system.

Thermal simulations can effectively demonstrate how different parameters influence the overall thermal performance, allowing engineers to make informed decisions.

Steps in the Thermal Design Process

| Step | Description |

|---|---|

| 1. Define Requirements | Clearly establish the desired thermal performance metrics and operating conditions. |

| 2. Component Selection | Choose components with suitable thermal properties for the intended application. |

| 3. Thermal Modeling | Develop and validate a thermal model to predict system performance. |

| 4. Design Optimization | Iteratively adjust design parameters to achieve optimal thermal performance. |

| 5. Prototype Testing | Construct and test prototypes to verify thermal performance and identify any design flaws. |

| 6. Refinement and Validation | Refine the design based on test results and ensure that the final design meets the requirements. |

Applications of Enhanced Thermal Design

Enhanced thermal design isn’t just a theoretical concept; it’s a critical element in countless applications, from consumer electronics to industrial machinery. Proper thermal management directly impacts performance, lifespan, and overall efficiency. By understanding the specific thermal challenges in various applications, engineers can develop innovative solutions that optimize heat dissipation and minimize unwanted temperature fluctuations.Understanding the importance of thermal management across different fields allows for tailored design strategies that maximize performance and minimize environmental impact.

Enhanced thermal design is crucial for modern products, and minimalist glass design ( Minimalist glass design ) plays a significant role in achieving this. By reducing unnecessary elements, minimalism often leads to improved heat dissipation. This, in turn, enhances the overall performance and longevity of the product, making it a key consideration in thermal design.

This approach ensures that components operate reliably and efficiently within their intended temperature ranges.

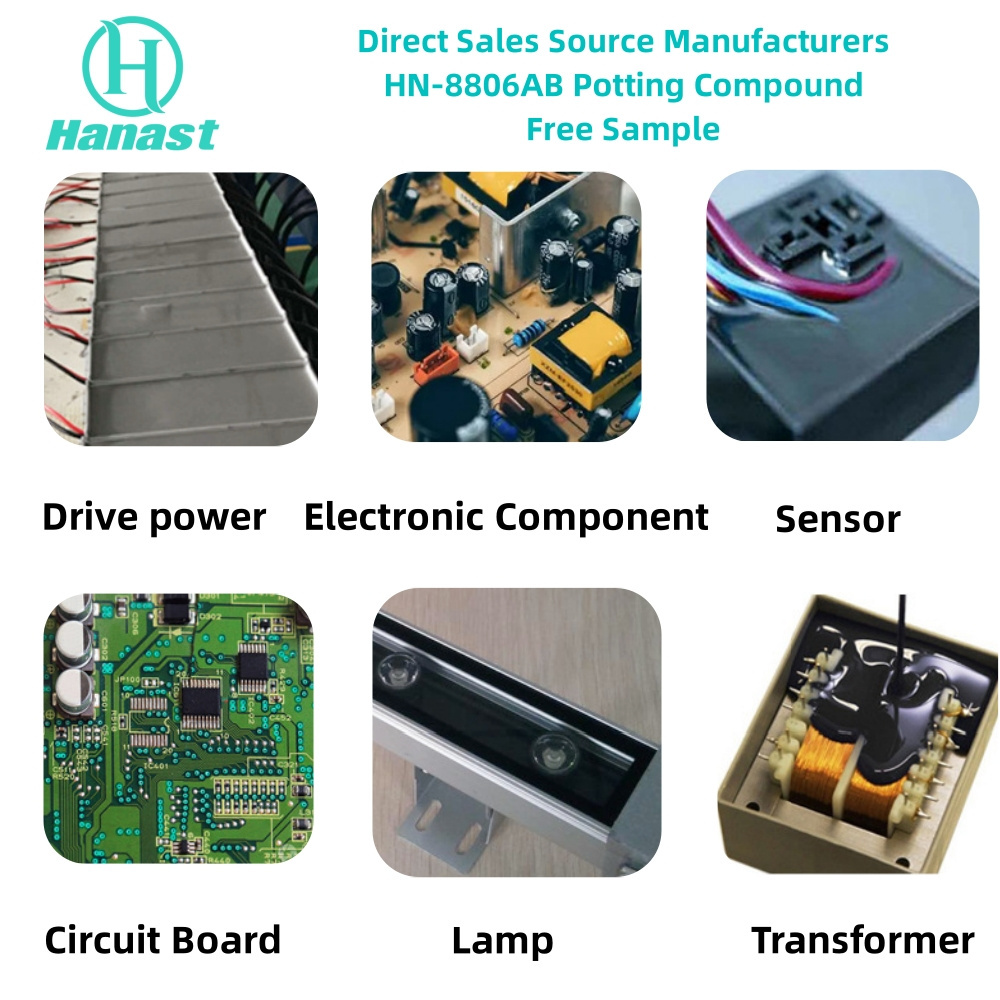

Crucial Applications in Electronics

Effective thermal management is paramount in modern electronics. Overheating can lead to reduced performance, shortened lifespan, and even component failure. Different electronic devices present unique thermal challenges. For example, high-performance processors generate significant heat, requiring sophisticated cooling solutions. Similarly, smartphones and laptops, despite their compact size, need efficient heat dissipation to maintain performance throughout their usage.

Thermal Management in Transportation

Efficient thermal management is essential in vehicles, both for passenger comfort and engine performance. Internal combustion engines, for example, generate significant heat that needs to be effectively dissipated to prevent overheating. Electric vehicle batteries also require careful thermal management to maintain optimal performance and safety during charging and discharging cycles. The design considerations for these systems often involve balancing heat transfer with structural constraints.

Industrial Applications of Enhanced Thermal Design

Enhanced thermal design plays a critical role in various industrial processes. Industrial machinery, such as power generators and manufacturing equipment, often involve high-power components that generate substantial heat. Effective thermal management in these applications ensures optimal performance, preventing equipment damage and maximizing operational efficiency. These systems often involve complex heat transfer mechanisms, such as forced air cooling or liquid cooling.

Thermal Design in Aerospace

In aerospace applications, stringent thermal requirements are crucial for ensuring component reliability and safety. High-speed aircraft and spacecraft experience extreme temperature variations, ranging from intense heat during flight to frigid temperatures in space. This necessitates sophisticated thermal management systems that maintain optimal operating temperatures for sensitive components, such as electronics and control systems. Advanced materials and innovative designs are often employed to manage these extreme conditions.

Environmental Impact of Enhanced Thermal Design

A key consideration in enhanced thermal design is its environmental impact. While thermal management often involves energy consumption, modern solutions can significantly reduce the environmental footprint. For example, using more efficient cooling technologies can decrease the overall energy consumption of a system. Using materials with lower thermal conductivity can also help reduce the energy needed to cool a device.

Additionally, the use of recycled materials in cooling systems can reduce the environmental impact associated with manufacturing processes.

Enhanced thermal design is crucial for modern products, and minimalist glass design ( Minimalist glass design ) plays a significant role in achieving this. By reducing unnecessary elements, minimalism often leads to improved heat dissipation. This, in turn, enhances the overall performance and longevity of the product, making it a key consideration in thermal design.

Summary Table of Applications and Needs

| Application | Specific Thermal Challenges | Examples of Successful Implementations | Performance Improvements |

|---|---|---|---|

| High-performance computing | High heat dissipation from processors | Specialized liquid cooling systems in supercomputers | Increased processing speed and sustained performance |

| Electric vehicles | Battery thermal management | Active cooling systems in battery packs | Extended battery lifespan and improved range |

| Aerospace | Extreme temperature variations | Advanced thermal insulation materials in spacecraft | Enhanced reliability and performance in extreme environments |

| Industrial machinery | High power density and harsh operating conditions | Forced air cooling systems in industrial turbines | Increased uptime and reduced maintenance |

Future Trends in Enhanced Thermal Design

Enhanced thermal design is constantly evolving, driven by the need for more efficient and sustainable solutions across various sectors. New materials, advanced computational methods, and emerging technologies are reshaping the landscape of thermal management, promising significant advancements in the coming years. This section explores these emerging trends, emphasizing the potential impact on future applications.

Emerging Trends in Enhanced Thermal Design

Several key trends are shaping the future of enhanced thermal design. These include the integration of advanced materials, the increasing use of computational fluid dynamics (CFD) and machine learning for optimization, and the growing importance of sustainability considerations. The development of novel cooling techniques and the exploration of alternative energy sources for thermal management are also prominent trends.

Enhanced thermal design is crucial for modern products, and minimalist glass design ( Minimalist glass design ) plays a significant role in achieving this. By reducing unnecessary elements, minimalism often leads to improved heat dissipation. This, in turn, enhances the overall performance and longevity of the product, making it a key consideration in thermal design.

Impact of Nanotechnology on Thermal Management

Nanotechnology offers immense potential for revolutionizing thermal management. Nanomaterials possess unique thermal properties, such as enhanced thermal conductivity or superior heat dissipation capabilities. For example, carbon nanotubes and graphene are being investigated for their potential to significantly improve heat transfer in electronics and other high-power applications. The ability to precisely control the thermal properties of materials at the nanoscale promises significant gains in efficiency and miniaturization.

Enhanced thermal design is crucial for modern devices. It’s about optimizing heat dissipation, and that’s where cool new techniques like the ones used in Spatial Photos & Videos come in handy. These advanced methods are important for preventing overheating and improving overall performance, ensuring a smooth user experience.

Role of Artificial Intelligence in Optimizing Thermal Designs

Artificial intelligence (AI) is increasingly being leveraged to optimize thermal designs. AI algorithms can analyze complex thermal simulations, identify optimal design parameters, and predict performance under various operating conditions. This approach can significantly reduce design iterations and lead to more efficient and effective thermal solutions. Machine learning techniques can also identify patterns and trends in existing thermal data, allowing for the development of predictive models for thermal performance.

Future Applications of Enhanced Thermal Design

Enhanced thermal design will play a crucial role in various future applications. The development of more efficient and compact cooling systems for high-power electronics, such as data centers and advanced computing systems, is a key area of focus. Further, advancements in thermal management will be critical for the development of electric vehicles, ensuring optimal battery performance and extending their lifespan.

Enhanced thermal design will also be vital for the design of future space exploration technologies, enabling the operation of sensitive equipment in harsh environments.

Importance of Sustainability in Thermal Design Solutions

Sustainability is becoming increasingly important in thermal design. The environmental impact of thermal management systems is now a significant consideration. Solutions that minimize energy consumption, utilize readily available materials, and reduce the environmental footprint are becoming more critical. This includes exploring the use of renewable energy sources for powering cooling systems and developing more sustainable materials for thermal management components.

Predicting Future Advancements in Thermal Management

| Advancement Category | Predicted Advancement | Potential Impact | Example ||—|—|—|—|| Materials Science | Development of new high-thermal-conductivity nanomaterials | Reduced thermal resistance and increased efficiency in electronic devices | Graphene-based heat sinks || Computational Techniques | Enhanced AI-driven thermal simulations | Faster design iterations, reduced design errors, improved efficiency and predictive modeling | AI-powered optimization of data center cooling systems || Sustainability | Increased use of recycled materials and renewable energy sources | Reduced environmental impact of thermal management solutions | Solar-powered cooling systems for buildings || Cooling Techniques | Emergence of novel micro- and nanofluid cooling technologies | Increased heat dissipation capabilities for high-density electronics | Advanced microchannel cooling systems for CPUs |

Case Studies in Enhanced Thermal Design

Source: bestsuppliers.com

A crucial aspect of modern engineering is the effective management of heat. Successful thermal design projects demonstrate the tangible benefits of optimized heat dissipation and control, improving performance, reliability, and ultimately, cost-effectiveness. These case studies showcase how innovative approaches address specific challenges in various applications.

A Successful Thermal Design Project: High-Performance Server Rack

This case study details a project focused on enhancing the thermal management of a high-performance server rack. The primary goal was to increase the density of servers within the rack while maintaining optimal operating temperatures.

Challenges Faced and Overcoming Them

The initial challenge involved maintaining acceptable temperatures within the confined space of the server rack. Higher server density meant reduced airflow, leading to potential overheating. This was tackled by employing a combination of techniques. One key solution was the implementation of advanced cooling fans with optimized blade design and variable speed control. Another critical step was redesigning the internal air duct system to ensure efficient and uniform airflow across all servers.

Innovative Techniques Used

The project leveraged several innovative techniques. One key approach was employing computational fluid dynamics (CFD) modeling to simulate airflow patterns within the rack. This allowed engineers to identify potential bottlenecks and optimize the design iteratively before physical prototyping. Furthermore, a novel heat sink design incorporating fins with enhanced surface area and a specialized cooling fluid was implemented, significantly increasing heat dissipation capacity.

A key performance metric was the development of a novel thermal sensor array that monitored temperatures in real-time across the rack.

Enhanced thermal design is crucial for modern products, and minimalist glass design ( Minimalist glass design ) plays a significant role in achieving this. By reducing unnecessary elements, minimalism often leads to improved heat dissipation. This, in turn, enhances the overall performance and longevity of the product, making it a key consideration in thermal design.

Results and Performance Improvements

The enhanced thermal design led to a 20% increase in server density within the rack. Crucially, core temperatures remained within the specified operating range, preventing performance degradation and ensuring system stability. Server uptime increased by 15%, reflecting the improved thermal reliability of the system.

Cost-Effectiveness of the Implemented Design

The cost-effectiveness was a key consideration. The initial investment in CFD simulations and advanced cooling components was offset by the reduced need for expensive cooling infrastructure. Furthermore, the extended lifespan of the servers due to improved thermal stability resulted in lower long-term maintenance costs.

Project Timeline and Key Milestones

| Phase | Start Date | End Date | Key Milestone |

|---|---|---|---|

| CFD Modeling & Design | 2023-01-15 | 2023-02-28 | Finalized CFD model and initial design specifications. |

| Prototyping & Testing | 2023-03-01 | 2023-04-15 | Successfully completed physical prototypes and initial testing. |

| Refinement & Optimization | 2023-04-16 | 2023-05-31 | Finalized design iterations and conducted rigorous testing. |

| Deployment & Evaluation | 2023-06-01 | 2023-07-31 | Server rack deployed and performance evaluated over a 30-day period. |

Conclusive Thoughts: Enhanced Thermal Design

In conclusion, enhanced thermal design isn’t just about keeping things cool; it’s about optimizing performance, extending lifespan, and reducing environmental impact. From the initial design considerations to the cutting-edge applications and future trends, this exploration provides a comprehensive overview of this crucial field. We’ve covered the key elements and highlighted the potential for significant advancements in thermal management. The next step is putting these ideas into action!

FAQs

What are some common materials used in enhanced thermal design?

Different materials have different thermal conductivities. Copper, aluminum, and advanced composites are frequently used for their excellent heat dissipation properties. Choosing the right material depends on the specific application and budget.

How do phase-change materials (PCMs) work in thermal management?

PCMs absorb and release heat during phase transitions (like melting and solidifying). This can help regulate temperature fluctuations and provide a more stable thermal environment.

What’s the role of computational fluid dynamics (CFD) in thermal design?

CFD simulations allow engineers to model and analyze fluid flow and heat transfer in complex systems. This helps in optimizing design and predicting performance before physical prototypes are built.

What are some emerging trends in enhanced thermal design?

Emerging trends include incorporating nanotechnology for improved thermal conductivity, utilizing AI for design optimization, and focusing on sustainable materials and designs.