OLED display technology is revolutionizing how we see the world. From vibrant smartphones to stunning televisions, OLED displays offer incredible picture quality and energy efficiency. This overview explores the fascinating world of OLED displays, covering everything from their creation to their many applications and the challenges ahead.

OLED displays are built using organic materials, which emit light when an electric current passes through them. This unique characteristic allows for incredibly thin, flexible displays with a wide color gamut and deep blacks. They’ve quickly become a favorite in high-end devices, pushing the boundaries of what’s possible in display technology.

Introduction to OLED Displays

OLED displays, or Organic Light-Emitting Diode displays, are a revolutionary technology that’s rapidly changing the landscape of electronic devices. Unlike traditional LCDs, which rely on backlight to illuminate pixels, OLEDs emit light directly from the organic materials themselves. This fundamental difference leads to several key advantages, making OLEDs a desirable choice for various applications.OLED technology harnesses the properties of organic materials to create light.

These materials, when an electric current passes through them, emit light. The color of the light depends on the specific organic material used. This process of electroluminescence is the core principle behind OLED display operation.

Historical Evolution of OLED Displays

The concept of organic light-emitting diodes (OLEDs) dates back to the 1960s. However, significant advancements and breakthroughs occurred in the following decades, leading to practical display applications. Early research focused on understanding the properties of organic materials and their potential for light emission. The development of efficient and stable organic materials was crucial in the progress towards functional OLED displays.

Key milestones in the development included the creation of various organic materials and the optimization of device structures, paving the way for practical display technology.

Types of OLED Displays

OLED displays are categorized into passive matrix and active matrix types, each with its own characteristics. Passive matrix OLEDs are simpler and less expensive to manufacture, but they have limitations in terms of refresh rate and resolution. Active matrix OLEDs, on the other hand, offer higher resolution, faster response times, and improved brightness, making them suitable for a wider range of applications.

Advantages of OLED Displays over Other Technologies

OLED displays offer several advantages over other display technologies, such as LCDs. These advantages stem from the fundamental difference in how light is generated. The direct light emission of OLEDs translates to several improvements. OLEDs exhibit significantly higher contrast ratios, meaning they can display darker blacks and brighter whites. They also consume less power, which is a significant advantage for battery-powered devices.

Another key benefit is their ability to create flexible and transparent displays, enabling new possibilities for device design and integration.

Comparison of OLED and LCD Displays

| Feature | OLED | LCD |

|---|---|---|

| Power Consumption | Lower | Higher |

| Response Time | Faster | Slower |

| Contrast Ratio | Higher | Lower |

| Color Reproduction | Excellent | Good |

| Viewing Angle | Good | Fair |

| Manufacturing Cost | Higher | Lower |

| Flexibility | Potentially flexible | Generally rigid |

The table above highlights the key differences between OLED and LCD displays across various crucial factors. These differences are significant, impacting the suitability of each technology for different applications. The choice between OLED and LCD hinges on the specific needs and priorities of the application. For instance, in mobile phones, the benefits of lower power consumption and faster response times in OLEDs make them a strong contender.

In contrast, the lower cost of LCDs might make them preferable for large-scale displays in certain situations.

OLED Display Manufacturing Processes

OLED display manufacturing is a complex process, requiring precision and control at each stage. Different methods exist, each with its own strengths and weaknesses, impacting the final display quality and cost. Understanding these processes is crucial for evaluating the potential and limitations of OLED technology.

Key Stages in OLED Display Production

The creation of an OLED display involves several crucial steps. These stages are intricately linked, with each impacting the overall performance and characteristics of the final product. From material preparation to the final assembly, meticulous attention to detail is paramount.

OLED displays are awesome for their vibrant colors and sharp images, but you might want to consider privacy if you’re using them in a public space. That’s where Privacy glass comes in handy. It’s a great way to maintain visibility while keeping your screen’s contents private, making OLED displays even more versatile for various situations.

- Material Preparation: High-purity materials are meticulously processed to ensure the required properties for optimal device performance. This stage involves purification, characterization, and precise control over the material composition to minimize defects. Variations in material quality can significantly affect the device’s efficiency, color accuracy, and longevity.

- Thin Film Deposition: Precisely controlled deposition of organic materials onto a substrate is crucial for creating the active OLED layers. Techniques like thermal evaporation, sputtering, and inkjet printing are employed. The choice of technique directly influences the uniformity and quality of the thin films, thus affecting the device’s performance characteristics.

- Pattern Formation: The active material is patterned to form the desired pixel structure. Photolithography and etching are commonly used to create intricate patterns with high precision. The accuracy of pattern formation directly impacts the display’s resolution and visual quality.

- Device Fabrication: After patterning, various steps are taken to complete the OLED device. This includes the deposition of additional layers, contacts, and encapsulation. These layers protect the sensitive OLED material from environmental factors, ensuring the long-term stability and reliability of the display.

- Assembly and Testing: The fabricated OLED devices are assembled onto the final substrate, along with other components. Rigorous testing is conducted to ensure that the displays meet the required specifications for brightness, contrast, color gamut, and viewing angles. These tests are vital for identifying and rectifying any issues before the display is released.

Materials Used in OLED Display Fabrication

A variety of organic and inorganic materials are used in the production of OLED displays. The specific materials and their ratios influence the performance and properties of the final product.

| Material | Role |

|---|---|

| Organic Materials (e.g., small molecule, polymer) | Form the light-emitting layer (EML) and other active layers, dictating the device’s color and efficiency. The type of organic material used significantly affects the device’s performance characteristics. |

| Inorganic Materials (e.g., metal oxides, conductive polymers) | Serve as electrodes, charge transport layers, and other supporting components. The selection of inorganic materials affects the device’s conductivity and stability. |

| Substrate Materials (e.g., glass, plastic) | Provide the physical support for the OLED device. The choice of substrate influences the flexibility, weight, and cost of the display. |

| Encapsulation Materials | Protect the OLED device from moisture, oxygen, and other environmental factors, extending its lifespan and reliability. |

Challenges and Limitations of OLED Display Manufacturing

Manufacturing OLED displays presents several challenges. The delicate nature of organic materials and the stringent process requirements contribute to these difficulties.

- Material Purity and Uniformity: Maintaining high purity and uniformity of organic materials across the entire production process is essential. Small variations in material quality can lead to significant inconsistencies in device performance.

- Process Control: The manufacturing process requires precise control over various parameters, such as temperature, pressure, and deposition rates, to achieve optimal device characteristics. Variations in these parameters can affect the quality and performance of the display.

- Scalability: Scaling up the production of OLED displays while maintaining high quality and consistency remains a significant challenge. Developing efficient and cost-effective large-scale manufacturing processes is crucial for widespread adoption.

- Yield Rate: Achieving high yield rates in OLED display production is crucial for reducing manufacturing costs. Strategies to improve the yield rate are continuously being investigated.

Comparison of Manufacturing Techniques

Different techniques are used for depositing the organic layers in OLED displays. Each technique offers advantages and disadvantages regarding cost, efficiency, and quality.

- Thermal Evaporation: A common technique that involves vaporizing materials and depositing them onto a substrate. This method is often used for high-quality displays due to its ability to create high-purity layers.

- Organic Vapor Phase Deposition (OVPD): A technique that involves the controlled vaporization of organic materials. OVPD is known for its ability to deposit high-quality films, particularly in large-scale production.

- Inkjet Printing: A promising technique for producing flexible and low-cost OLED displays. This technique involves the precise deposition of materials through inkjet nozzles.

Impact of Manufacturing Processes on Display Quality

The choice of manufacturing process directly impacts the quality of the final OLED display. Factors such as uniformity, resolution, and color accuracy are all affected by the methods used.

- Resolution: Advanced patterning techniques are necessary to achieve high-resolution OLED displays. The resolution and pixel density are directly influenced by the patterning accuracy during the fabrication process.

- Color Accuracy: The quality of the organic materials and the uniformity of the deposition process are crucial for achieving accurate color reproduction. Variations in the material properties can result in color inaccuracies.

- Efficiency: Optimizing the deposition process and material selection are crucial for achieving high efficiency in OLED displays. The choice of deposition technique and material affects the light output and energy consumption of the device.

OLED Display Characteristics and Performance

OLED displays offer a compelling blend of advantages over traditional display technologies, but their performance is also influenced by various factors. Understanding these characteristics is crucial for evaluating their suitability for different applications.OLED displays’ inherent properties, like self-emission and flexibility, translate into unique advantages, but these attributes are also intertwined with limitations. Analyzing their performance metrics, like luminance, contrast, and color gamut, is essential to understanding their strengths and weaknesses in specific applications.

Luminance and Contrast Ratio

OLED displays excel in achieving high luminance levels, crucial for bright outdoor viewing or high-resolution video content. The self-emissive nature of OLEDs allows for direct light generation, eliminating the need for backlights, leading to thinner displays and potentially lower power consumption. Contrast ratios, a measure of the difference between the brightest and darkest areas, are typically excellent in OLEDs, contributing to deep blacks and vivid colors.

Color Gamut

OLED displays boast a wide color gamut, meaning they can reproduce a broader range of colors. This characteristic translates into vibrant and realistic imagery, crucial for applications requiring accurate color reproduction, like professional design work or high-end gaming. Different OLED display types, like those using different phosphors, can achieve varying color gamuts.

OLED Display Types and Color Reproduction

Various OLED display types exist, each with its own strengths and limitations. Organic light-emitting diodes (OLEDs) are classified into different types based on the materials used in their fabrication. These differences affect their color reproduction capabilities. For example, some OLEDs may excel at reproducing reds and greens, while others may have superior blue color reproduction.

Lifespan and Reliability

OLED displays generally exhibit a decent lifespan, but variations exist. Factors like ambient temperature and operational conditions can impact their longevity. While OLEDs often have a longer lifespan than some LCD technologies, they may not match the extreme longevity of certain LED technologies.

Comparison with Other Display Technologies

Compared to LCDs, OLED displays generally provide superior contrast ratios, wider color gamuts, and potentially lower power consumption. However, LCDs are often more cost-effective for mass production. Plasma displays, another older technology, have been largely superseded by OLEDs and LCDs. OLEDs offer a more seamless viewing experience with deeper blacks and better color reproduction, but their lifespan and cost still need careful consideration.

OLED displays are pretty cool, offering vibrant colors and super thin designs. But the materials behind the scenes, like the obscure glass used in their manufacturing process, Obscure glass , are fascinating too. This special glass plays a crucial role in ensuring the display’s performance and longevity, which ultimately impacts the overall quality of the OLED display.

OLED Display Performance Metrics Comparison

| Display Technology | Luminance (cd/m²) | Contrast Ratio | Color Gamut (NTSC%) | Lifespan (hours) | Cost |

|---|---|---|---|---|---|

| OLED | 1000-10000+ | 1000:1 – 1,000,000:1+ | 90-100+ | 10,000-50,000+ | Medium-High |

| LCD | 300-1000+ | 500:1 – 1000:1+ | 70-90 | 30,000-100,000+ | Low-Medium |

| Plasma | 200-800+ | 1000:1 – 10,000:1+ | 70-80 | 30,000-100,000+ | High |

Applications of OLED Displays

OLED displays, with their unique characteristics, are rapidly expanding into a wide range of applications. Their inherent advantages, such as high contrast ratios, vibrant colors, and flexibility, are driving innovation across industries. From mobile devices to televisions and beyond, OLED technology is transforming how we interact with technology.

Mobile Device Applications

OLED displays excel in mobile devices due to their low power consumption and high brightness. This translates to longer battery life and a more immersive viewing experience for users. Smartphones, tablets, and e-readers are prime examples of how OLEDs improve user experience. The reduced thickness and weight of OLED panels contribute to more compact and portable devices.

Television Applications

OLED televisions have revolutionized the home entertainment experience. Their exceptional contrast ratio produces deep blacks and vivid colors, delivering a superior picture quality compared to traditional LCD TVs. The self-emissive nature of OLED pixels eliminates the need for backlights, resulting in thinner displays and improved viewing angles. This technology allows for more immersive and realistic viewing experiences, especially for action-packed films and games.

Wearable Applications

The flexibility and lightweight nature of OLEDs make them ideal for wearable devices. Smartwatches, fitness trackers, and augmented reality (AR) glasses are increasingly incorporating OLED displays. The ability to create curved or flexible displays perfectly complements the design and function of these devices, enabling a seamless user experience.

Emerging Applications

Beyond the established applications, OLED technology is venturing into new and exciting areas. Transparent OLED displays are being explored for applications in automotive interiors and architectural designs. Flexible OLED displays could transform signage and interactive displays, providing dynamic and adaptable visual experiences. Furthermore, the potential of integrating OLED displays into clothing and other wearable items is an active area of research.

Growth and Future Prospects

The market for OLED displays is experiencing substantial growth, driven by increasing demand from various industries. The continued development of new manufacturing techniques and the exploration of novel applications will further propel this growth. OLED displays are expected to dominate various sectors, replacing traditional technologies due to their superior performance and versatility. The ongoing innovation in this field promises even more exciting and transformative applications in the future.

Table of OLED Display Applications and Benefits

| Application | Benefits |

|---|---|

| Mobile Devices | Longer battery life, high brightness, immersive viewing experience, compact design |

| Televisions | Superior picture quality (deep blacks, vivid colors), thinner displays, improved viewing angles |

| Wearables | Flexibility, lightweight design, seamless user experience, curved or flexible displays |

| Transparent Displays | Integration into automotive interiors and architectural designs, dynamic visual experiences |

| Flexible Displays | Transformative signage and interactive displays, adaptable visual experiences, integration into clothing and other wearables |

Challenges and Future Trends in OLED Displays

OLED displays, with their vibrant colors, high contrast ratios, and thin profiles, are rapidly gaining popularity. However, several challenges remain in their development and widespread adoption. These obstacles, coupled with ongoing research and development, pave the way for exciting future trends that promise to further enhance the capabilities and applications of OLED technology.

Current Challenges in OLED Display Development

OLED displays, while impressive, face limitations in areas like manufacturing complexity, material science, and cost. Achieving consistent, high-quality production across large-scale manufacturing remains a significant hurdle. Material stability and lifespan are also critical concerns, especially in high-temperature or harsh environments. The high initial cost of OLED production, compared to LCD technology, is another factor hindering widespread consumer adoption.

Ongoing Research and Development Efforts

Extensive research and development are actively addressing these challenges. Scientists and engineers are exploring novel materials with enhanced stability and performance, aiming to improve the lifespan and reliability of OLED devices. Advanced manufacturing techniques are being developed to streamline the production process and reduce costs. Furthermore, research into new device architectures and driving methods are enhancing the display’s performance and efficiency.

Potential Future Trends and Innovations

Several promising future trends are emerging in OLED display technology. One area of significant interest is the development of flexible and foldable OLED displays, which have the potential to revolutionize mobile devices and wearable technology. Another key area is the exploration of new materials and architectures for improved color gamut and brightness. Additionally, advancements in micro-OLED technology hold the promise of higher resolution and miniaturization, opening up possibilities for applications like augmented reality (AR) and virtual reality (VR) displays.

OLED displays are super cool, using way less power than traditional screens. Think about how that translates to energy-saving solutions like Energy-efficient windows , and you start to see the potential for similar advancements in display technology. Ultimately, OLEDs are a huge step forward in eco-friendly tech.

Emerging Research Directions for Improving OLED Displays

Research into new materials is crucial for enhancing OLED performance. For instance, researchers are investigating organic materials with higher electron mobility and improved stability, which can lead to faster response times and longer lifespans. Advanced device architectures, like those incorporating micro-LED backlighting, are being explored to improve brightness and contrast. Furthermore, advancements in display drivers are aimed at achieving more efficient and dynamic control over pixel illumination.

Potential Impact of Future Trends on Industries

The potential innovations in OLED displays will have significant impacts across diverse industries. The flexible and foldable displays will transform the design and functionality of mobile phones, tablets, and wearables. Higher resolution and miniaturized OLEDs will create immersive AR and VR experiences, potentially impacting gaming, healthcare, and education. Improved brightness and color gamut will enhance the visual experience in professional applications, including medical imaging and scientific visualization.

Key Challenges and Future Trends in OLED Displays

| Challenges | Future Trends |

|---|---|

| Manufacturing complexity and scalability | Development of advanced, cost-effective manufacturing techniques |

| Material stability and lifespan | Exploration of novel, stable organic materials |

| High initial cost of production | Advanced manufacturing processes to reduce costs |

| Limited color gamut and brightness in certain applications | Development of new device architectures (e.g., micro-LED integration) |

| Power consumption | Improved display drivers and power management techniques |

OLED Display Design Considerations

OLED displays, known for their vibrant colors, low power consumption, and lightweight nature, require careful design considerations to optimize performance. These considerations span from the fundamental structure to the advanced requirements for high resolution and flexibility. Understanding these factors is crucial for achieving displays with the desired characteristics for various applications.

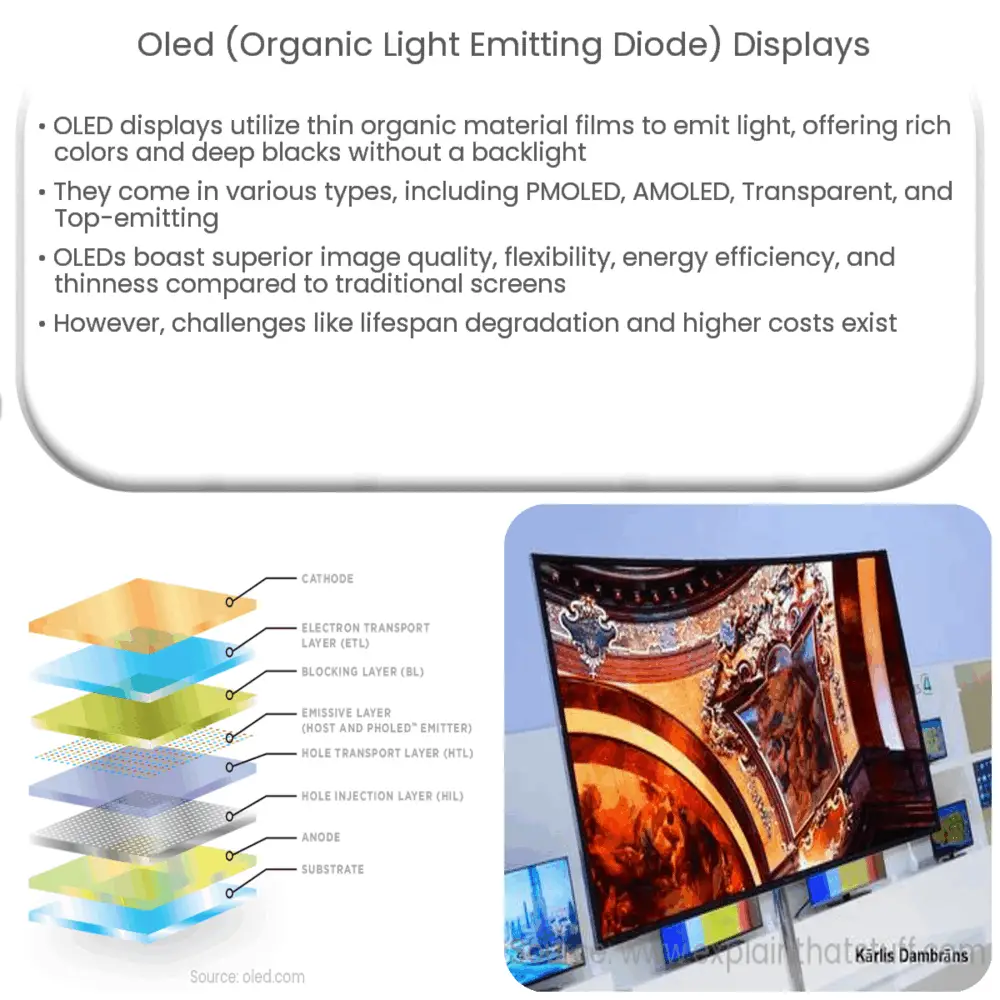

Basic Schematic Diagram of a Typical OLED Display Structure

The fundamental structure of an OLED display involves several layers. A simplified schematic diagram shows a substrate, typically glass or plastic, coated with an anode layer. This anode layer is followed by an organic light-emitting layer, a hole injection layer, and an electron injection layer. Finally, a cathode layer completes the structure. The substrate serves as the foundation for the entire display assembly.

OLED displays are amazing, offering vibrant colours and super thin profiles. They’re perfect for sleek designs, but imagine pairing them with a revolutionary folding glass wall, like the ones found at Folding glass wall. The possibilities for immersive viewing experiences are endless, combining the best of modern technology.

The organic light-emitting layer, composed of organic materials, is responsible for emitting light when an electrical current passes through it. This light is then emitted through the top surface of the display.

Factors Affecting the Design of OLED Displays

Several key factors influence the design of OLED displays. Material properties, such as the emission spectrum and efficiency of the organic light-emitting materials, are critical. The uniformity of the light emission across the entire display area significantly impacts the image quality. The thickness and uniformity of the organic layers are crucial for achieving consistent performance and preventing defects.

Furthermore, the stability of the organic materials over time and under varying environmental conditions is vital for long-term reliability. The cost of the materials and manufacturing processes also play a role in determining the commercial viability of the display.

Role of Substrate Material Selection in OLED Display Design

Substrate material selection is a crucial aspect of OLED display design. Glass substrates offer high mechanical strength and stability, enabling the fabrication of displays with complex structures. However, they are rigid, limiting flexibility. Plastic substrates, while flexible, often exhibit lower mechanical strength compared to glass, impacting the overall durability of the display. The choice between glass and plastic depends on the specific application requirements.

For example, a flexible display for a smartphone would likely favor a plastic substrate, while a high-end television would likely use a glass substrate. The thermal expansion coefficients of the substrate material are also considered for minimizing stress and potential damage during the manufacturing and operational life of the display.

OLED displays are super cool, offering vibrant colors and super thin designs. But, for a truly immersive experience, you need to consider soundproofing. Think about how important soundproof glass is in a modern home theater setup, or even a quiet workspace. Soundproof glass helps block out unwanted noise, which is great for enjoying your OLED display without distractions.

Ultimately, a good OLED display needs a supportive environment, like a soundproofed room to really shine.

Design Considerations for High-Resolution OLED Displays

High-resolution OLED displays require careful consideration of pixel pitch and arrangement. Smaller pixel pitches allow for higher resolution, but they also demand more precise control during manufacturing. The arrangement of pixels and the addressing scheme significantly impact the overall display performance. Pixel driving circuits must be carefully designed to handle the increased data flow associated with high resolutions, ensuring fast response times and minimal image artifacts.

Comparison of Design Considerations for Flexible OLED Displays with Rigid Ones

Flexible OLED displays demand different design considerations compared to rigid displays. The flexibility of the substrate necessitates the use of more flexible materials and design structures for the other layers. The manufacturing processes must be adjusted to accommodate the flexibility of the substrate, while ensuring the display maintains its structural integrity and functionality. The overall packaging and encapsulation methods are critical to protect the delicate components of the flexible display.

Rigid displays, on the other hand, often benefit from simpler design and fabrication procedures due to the inherent stability of the substrate.

Design Parameters for OLED Displays and Their Implications

| Design Parameter | Description | Implications |

|---|---|---|

| Pixel Pitch | Distance between adjacent pixels | Smaller pitch allows for higher resolution, but demands more precise manufacturing |

| Substrate Material | Material used as the base for the display | Choice affects flexibility, strength, and manufacturing costs |

| Organic Material Properties | Characteristics of light-emitting materials | Impact emission spectrum, efficiency, and long-term stability |

| Encapsulation | Protective layer to prevent degradation | Crucial for long-term reliability, especially for flexible displays |

| Driving Circuit Design | Methods for activating pixels | Impacts response time and image quality at high resolutions |

Last Word

Source: electricity-magnetism.org

In conclusion, OLED displays are a remarkable technological advancement, offering a superior viewing experience across diverse applications. While challenges remain in manufacturing and cost, the future of OLED displays looks promising, with ongoing research and development continually pushing the boundaries of what’s possible. From sleek smartphones to immersive televisions, OLED displays are poised to dominate the display market for years to come.

Detailed FAQs: OLED Display

What are the key differences between passive and active matrix OLED displays?

Passive matrix OLEDs use a simpler, less expensive structure, but active matrix OLEDs offer much faster response times and higher resolutions, making them ideal for applications requiring fast-moving images.

How long do OLED displays typically last?

OLED displays generally have a long lifespan, but the exact duration depends on usage patterns and environmental factors. Under typical use, they can last for several years.

What are some emerging applications for OLED technology?

Beyond smartphones and TVs, OLED technology is being explored for applications like flexible wearables, holographic displays, and even in automotive displays.

What are the main challenges in OLED display manufacturing?

Manufacturing OLED displays is complex and involves precise control over materials and processes. Cost-effectiveness and scalability are significant challenges.