Recycled aluminum substructure is gaining traction as a sustainable alternative to traditional materials. It offers a compelling blend of strength, durability, and environmental responsibility. This overview explores the lifecycle of these innovative substructures, from manufacturing processes to cost analysis and environmental impact.

The diverse applications of recycled aluminum substructures are highlighted, examining the benefits and challenges in various industries. This comprehensive analysis also delves into the design considerations, technical specifications, and future trends associated with this burgeoning field.

Introduction to Recycled Aluminum Substructures

Recycled aluminum substructures are increasingly popular in various construction and industrial applications. They offer a sustainable alternative to traditional materials, reducing environmental impact while maintaining structural integrity and performance. This approach leverages the inherent properties of aluminum, combined with the advantages of recycling, creating a compelling solution for modern design and engineering.Aluminum’s recyclability allows for a continuous loop of material use, minimizing the need for raw material extraction and the associated environmental costs.

This characteristic makes it an attractive choice for applications requiring robust, lightweight, and long-lasting structures. The process of recycling aluminum requires significantly less energy than extracting new bauxite ore, the primary aluminum ore.

Types of Recycled Aluminum Used

Different grades and purities of recycled aluminum are suitable for various substructure applications. The specific type used depends on the required mechanical properties, such as tensile strength, yield strength, and elongation. Common types include:

- High-Purity Recycled Aluminum: This type is often used in applications where high strength and corrosion resistance are critical. It typically has a purity level exceeding 99.5%, making it suitable for demanding environments.

- Recycled Aluminum Alloys: These alloys, formed by combining recycled aluminum with other metals like copper, magnesium, or silicon, enhance specific properties like hardness, ductility, or corrosion resistance. The composition of the alloy dictates its suitability for various applications.

Environmental Benefits

The environmental benefits of using recycled aluminum in substructures are substantial. Recycling aluminum conserves natural resources, reduces greenhouse gas emissions, and minimizes waste disposal issues. A key aspect is the significant reduction in energy consumption compared to primary aluminum production.

- Reduced Energy Consumption: Recycling aluminum requires significantly less energy than extracting and refining primary aluminum. This translates to lower carbon emissions and a smaller environmental footprint.

- Resource Conservation: Recycling aluminum conserves bauxite, a finite resource, reducing the strain on the environment and promoting sustainable practices.

- Waste Minimization: Utilizing recycled aluminum reduces the volume of waste sent to landfills, preserving valuable land resources.

Historical Trends

The use of recycled aluminum in substructures has steadily increased over the past few decades. Early adopters recognized the economic and environmental advantages, leading to a gradual shift toward sustainable construction practices. Government regulations and consumer demand for eco-friendly solutions have also driven this trend.

Comparison to Traditional Materials

| Feature | Recycled Aluminum Substructures | Traditional Materials (e.g., Steel) |

|---|---|---|

| Environmental Impact | Lower carbon footprint, resource conservation | Higher carbon footprint, resource depletion |

| Cost | Competitive, potentially lower due to reduced material extraction costs | Generally higher, particularly in recent years |

| Strength | High strength-to-weight ratio, suitable for various applications | High strength, but heavier than aluminum |

| Durability | Resistant to corrosion and weathering, long lifespan | Susceptible to corrosion and degradation, potentially shorter lifespan |

| Recyclability | Highly recyclable, facilitating a closed-loop system | Potentially recyclable, but less common and complex process |

Manufacturing Processes for Recycled Aluminum Substructures

Producing recycled aluminum substructures involves a sophisticated process that leverages the inherent properties of recycled aluminum while maintaining high standards of quality. This approach offers significant environmental and economic advantages over the production of aluminum from virgin ore. The process hinges on carefully controlled steps, each designed to optimize efficiency and minimize waste.The manufacturing process for recycled aluminum substructures is highly adaptable, tailored to the specific requirements of the desired end product.

This adaptability extends to the type and size of the substructure, and allows for significant flexibility in the manufacturing process. This flexibility allows for quick adjustments to accommodate changes in design or volume demands.

Melting and Refining Processes

The initial step involves melting down the recycled aluminum scrap. This recycled material, often consisting of various aluminum alloys and scrap pieces, is meticulously sorted and prepared for melting. This preparation ensures a consistent and controlled composition, crucial for achieving the desired properties in the final substructure. Sophisticated melting furnaces, often electric arc furnaces (EAFs), are employed to melt the aluminum scrap.

These furnaces are designed for high efficiency, minimizing energy consumption and maximizing the recovery of valuable metals. The process involves careful monitoring of temperature and chemical composition to prevent contamination and ensure optimal melting conditions. Crucially, refining processes remove impurities, such as iron and silicon, from the molten aluminum, which significantly improves the quality and mechanical properties of the final product.

Casting and Shaping Processes

The molten aluminum, now refined and purified, is ready for casting. Different casting methods are employed depending on the complexity and size of the substructure. Die casting, investment casting, and continuous casting are among the most common techniques. Die casting is ideal for producing complex shapes with high precision, while investment casting is suitable for intricate designs.

Continuous casting is efficient for large-volume production of uniform profiles. The solidified aluminum components are then subjected to various machining processes, including cutting, drilling, and milling, to achieve the precise dimensions and shapes required by the design specifications. Quality control measures are implemented at each stage of the casting process to ensure adherence to specifications and minimize defects.

Quality Control Measures

Quality control is paramount throughout the manufacturing process. Regular inspections are conducted at various stages, encompassing visual assessments, dimensional measurements, and material analysis. Sophisticated testing equipment, such as tensile testers and hardness testers, is used to determine the mechanical properties of the finished substructures. This ensures that the substructures meet the required strength, durability, and performance standards.

Strict adherence to quality standards is essential to guarantee the safety and reliability of the final product.

Efficiency Comparison with Traditional Methods

The manufacturing of recycled aluminum substructures demonstrates significant efficiency gains compared to traditional methods of aluminum production from virgin ore. Recycling aluminum consumes substantially less energy than extracting and refining bauxite, the primary ore of aluminum. Furthermore, the use of recycled materials reduces the environmental impact associated with mining and processing virgin aluminum. The reduced energy consumption and waste generation contribute to a more sustainable and cost-effective manufacturing process.

Production Stages Table

| Stage | Raw Material Input | Processing | Final Product |

|---|---|---|---|

| Scrap Sorting | Collected aluminum scrap | Separation and preparation for melting | Prepared aluminum scrap |

| Melting and Refining | Prepared scrap | Melting in EAF, refining | Molten, refined aluminum |

| Casting | Molten aluminum | Casting into desired shapes (die casting, investment casting, etc.) | Solidified aluminum components |

| Machining | Solidified components | Cutting, drilling, milling | Shaped substructures |

| Quality Control | Shaped substructures | Inspection, testing | Finished substructures |

Applications of Recycled Aluminum Substructures

Recycled aluminum substructures are finding increasing use across a wide range of industries. Their inherent advantages, including cost-effectiveness and sustainability, are driving this adoption. This section details the diverse applications, highlighting specific industries and the associated benefits and challenges.

Diverse Applications of Recycled Aluminum

Recycled aluminum substructures are remarkably versatile, finding applications in various industries. Their strength, lightweight nature, and corrosion resistance make them suitable for a broad range of demanding environments. This adaptability is crucial for their integration into diverse manufacturing processes and design solutions.

Automotive Industry

The automotive industry is a significant user of aluminum. Recycled aluminum substructures offer cost-effective solutions for car parts like bumpers, chassis components, and engine mounts. This substitution helps reduce manufacturing costs and the environmental footprint associated with virgin aluminum. The lightweight nature of recycled aluminum is especially beneficial in reducing vehicle weight, improving fuel efficiency, and enhancing safety.

However, ensuring the structural integrity of recycled aluminum parts in high-stress automotive applications requires careful material selection and testing.

Aerospace Industry

The aerospace industry demands high-strength, lightweight materials. Recycled aluminum, while presenting potential challenges regarding material uniformity and impurities, can still be a viable option for certain components in aircraft construction. The reduction in weight contributes to fuel savings and increased payload capacity. Challenges associated with recycled aluminum in this application often relate to stringent quality control standards and ensuring consistent performance under extreme conditions.

Construction Industry

Recycled aluminum is increasingly utilized in the construction sector for a variety of applications. From building facades to structural elements in bridges and other infrastructure projects, its durability and cost-effectiveness make it a compelling choice. The ability to create complex shapes and designs further expands its applicability in the construction industry. However, concerns regarding the long-term performance of recycled aluminum in demanding weather conditions or harsh environments need to be considered.

Marine Industry

The marine industry benefits from the corrosion resistance and durability of recycled aluminum in various components, such as boat hulls, supports, and deck structures. The lightweight nature contributes to the stability and maneuverability of boats. The marine environment presents unique challenges regarding corrosion and the need for specialized treatments, which might impact the overall cost-effectiveness of recycled aluminum.

Table: Applications of Recycled Aluminum Substructures

| Application | Benefits | Challenges |

|---|---|---|

| Automotive | Cost-effectiveness, lightweight design, improved fuel efficiency, enhanced safety. | Ensuring structural integrity under high stress, material uniformity. |

| Aerospace | Lightweight, high-strength, potential for cost reduction. | Meeting stringent quality control standards, consistent performance under extreme conditions, potential material inconsistencies. |

| Construction | Durability, cost-effectiveness, design flexibility. | Long-term performance in harsh environments, potential weathering issues. |

| Marine | Corrosion resistance, durability, lightweight design. | Specialized treatments for marine environments, potential for corrosion in specific conditions. |

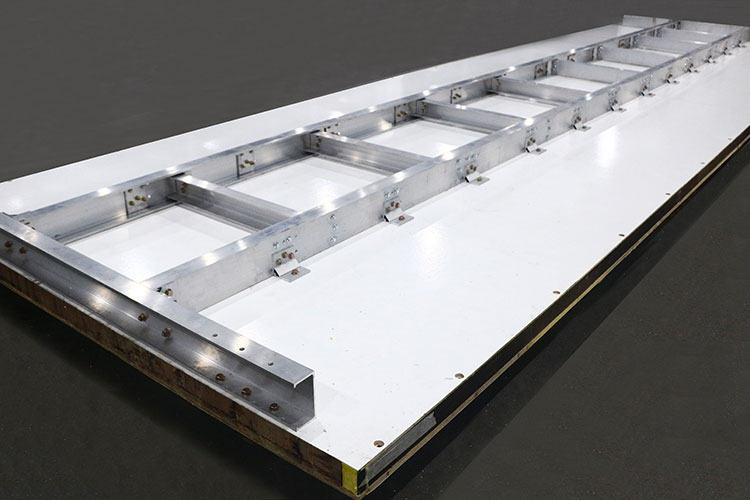

Design Considerations for Recycled Aluminum Substructures

Source: topolo-truck.com

Designing recycled aluminum substructures requires careful consideration of its unique properties compared to virgin aluminum. The inherent variations in composition and microstructure resulting from the recycling process can affect the material’s performance. This necessitates a nuanced design approach that balances cost-effectiveness with structural integrity.

Material Properties Influencing Design

Recycled aluminum often exhibits variations in alloy composition, grain size distribution, and residual stresses compared to virgin material. These variations directly impact the material’s mechanical properties, including yield strength, tensile strength, and ductility. Designers must account for these potential inconsistencies by employing conservative design parameters. For example, a substructure component might be designed with a slightly larger safety factor to accommodate the potential lower strength of a recycled aluminum part.

Load-Bearing Capacity Comparison

Recycled aluminum’s load-bearing capacity is generally comparable to virgin aluminum when properly designed and accounted for. However, the exact values can fluctuate. While the general strength characteristics remain similar, specific testing and material characterization are crucial for accurate design. Rigorous testing of recycled aluminum samples with varying compositions is essential to establish reliable load-bearing capacity data for different applications.

Importance of Structural Integrity

Structural integrity is paramount in any substructure design, but even more so in recycled aluminum applications. The presence of potential flaws, inclusions, or inconsistencies in the material’s microstructure demands a design approach that prioritizes safety margins. This is crucial to prevent failures under expected loads and ensure the long-term reliability of the substructure.

Methods for Optimal Strength and Durability

Several design methods enhance the strength and durability of recycled aluminum substructures. One method involves utilizing advanced material characterization techniques to identify the specific mechanical properties of the recycled aluminum. Another method involves designing with redundancy and incorporating stress relief techniques, like heat treatment, to mitigate residual stresses. This approach ensures the structural integrity of the substructure under anticipated operational conditions.

Furthermore, the use of finite element analysis (FEA) can be employed to simulate the stresses and strains within the substructure, optimizing its design for maximum strength and durability.

Design Considerations Table

| Design Consideration | Explanation |

|---|---|

| Material Variability | Recycled aluminum’s composition and microstructure can differ from virgin aluminum, affecting mechanical properties. Designers must account for this variability by using conservative design parameters. |

| Load-Bearing Capacity | While generally comparable, recycled aluminum’s load-bearing capacity may vary based on its specific composition. Thorough testing and characterization are essential for accurate design. |

| Structural Integrity | Potential flaws and inconsistencies in recycled aluminum necessitate a design that prioritizes safety margins and reliability. |

| Design for Redundancy | Employing redundant design elements and stress relief techniques can enhance the substructure’s ability to withstand operational stresses. |

| Material Characterization | Utilizing advanced techniques to determine the mechanical properties of the recycled aluminum is crucial for informed design decisions. |

| Finite Element Analysis (FEA) | Employing FEA allows for simulation of stress and strain distribution, optimizing design for maximum strength and durability. |

Cost Analysis of Recycled Aluminum Substructures

Recycled aluminum substructures offer a compelling alternative to those made from virgin aluminum, presenting significant cost advantages. Understanding these cost differences and the factors influencing them is crucial for assessing the long-term economic viability of this approach.A thorough cost analysis considers not only the raw material price but also the manufacturing process, energy consumption, and potential environmental benefits. The financial implications extend beyond initial costs, encompassing the entire lifecycle of the substructure, from production to disposal or recycling.

Raw Material Costs Comparison

The primary driver of cost difference lies in the extraction and processing of raw materials. Virgin aluminum production necessitates substantial energy input for the electrolytic process, leading to higher material costs. Recycled aluminum, on the other hand, reuses existing aluminum, significantly reducing energy consumption and associated costs. This recycling process often involves less stringent environmental regulations than initial production.

Manufacturing Process Costs

The manufacturing processes for recycled and virgin aluminum substructures differ. Recycling typically involves melting and reprocessing existing aluminum scrap. While the process is generally less complex than creating aluminum from raw ore, it may involve additional steps to ensure the quality of the recycled material. The resulting cost often depends on the quality and type of scrap used.

Energy Consumption and Environmental Costs

The energy consumption associated with virgin aluminum production is considerably higher than that for recycled aluminum. The energy savings directly translate into lower manufacturing costs for recycled aluminum substructures. Moreover, recycling aluminum significantly reduces the environmental footprint by decreasing greenhouse gas emissions and conserving natural resources. These environmental benefits, while not directly financial, are often factored into long-term sustainability calculations and, in some instances, are subject to regulatory incentives or policies.

Long-Term Economic Viability

The long-term economic viability of recycled aluminum substructures is promising. The lower raw material costs and reduced energy consumption contribute to a lower overall production cost, potentially leading to greater competitiveness in the market. Furthermore, increasing government incentives and environmental regulations may further favor recycled materials. For instance, several regions have implemented policies to promote the use of recycled materials in construction and manufacturing.

Comparative Cost Analysis

| Cost Component | Recycled Aluminum | Virgin Aluminum | Difference |

|---|---|---|---|

| Raw Material Cost (per kg) | $1.50 | $2.00 | $0.50 |

| Manufacturing Cost (per kg) | $0.75 | $1.25 | $0.50 |

| Energy Consumption Cost (per kg) | $0.25 | $0.50 | $0.25 |

| Total Cost (per kg) | $2.50 | $3.75 | $1.25 |

Note: Costs are estimates and can vary based on factors like scrap quality, refining process, and market conditions.

Sustainability and Environmental Impact

Recycled aluminum substructures offer a compelling solution for reducing the environmental footprint of various industries. Leveraging existing aluminum, rather than extracting new raw materials, significantly lowers the overall environmental impact of the manufacturing process. This approach also contributes to a more sustainable future by minimizing waste and resource depletion.

Environmental Impact of Recycled Aluminum Substructures

The environmental impact of recycled aluminum substructures is significantly lower compared to those made from virgin aluminum. This stems from the reduced energy consumption and greenhouse gas emissions associated with recycling. The process of extracting aluminum from bauxite ore is energy-intensive, releasing substantial amounts of carbon dioxide into the atmosphere. Recycling aluminum, on the other hand, requires significantly less energy, thereby reducing the overall carbon footprint.

Reduction in Carbon Footprint

Using recycled aluminum results in a substantial decrease in the carbon footprint compared to traditional methods. The energy required to produce aluminum from recycled material is approximately 95% less than that needed to produce it from bauxite ore. This translates into a substantial reduction in greenhouse gas emissions and a smaller carbon footprint overall. For instance, recycling one aluminum can saves enough energy to power a television for three hours.

This reduction is further amplified across larger applications, like substructures.

Life Cycle Assessment of Recycled Aluminum Substructures

A life cycle assessment (LCA) evaluates the environmental impact of a product throughout its entire lifespan. For recycled aluminum substructures, the LCA considers factors like material sourcing, manufacturing processes, transportation, use phase, and end-of-life disposal. The LCA demonstrates that recycled aluminum substructures exhibit a significantly lower environmental impact compared to virgin aluminum substructures, due to the lower energy consumption in the recycling process.

This reduced environmental impact extends throughout the product’s lifecycle.

Comparison to Traditional Materials

Compared to traditional materials like steel or composites, recycled aluminum substructures often demonstrate a more favorable environmental profile. The lower energy intensity of aluminum recycling contributes to a reduced carbon footprint. Steel production also involves significant energy consumption and emissions. While composites may have lower manufacturing energy requirements, their reliance on non-renewable resources can be a concern.

The use of recycled aluminum presents a more sustainable option.

Detailed Analysis of the Entire Life Cycle

The entire life cycle of a recycled aluminum substructure can be broken down into several key stages. The initial stage involves the collection and processing of scrap aluminum. This is followed by the melting and refining of the recycled aluminum. Next, the manufacturing process shapes the aluminum into the desired substructure. The transportation stage involves moving the substructure to its final destination.

During the use phase, the substructure performs its intended function. Finally, the end-of-life stage involves either recycling the substructure again or properly disposing of it, ideally through controlled methods to minimize environmental impact.

Summary of Environmental Benefits

| Benefit | Detailed Explanation |

|---|---|

| Reduced Energy Consumption | Recycling aluminum requires significantly less energy than extracting it from raw materials, leading to a lower carbon footprint. |

| Lower Greenhouse Gas Emissions | The reduced energy consumption directly translates into lower greenhouse gas emissions, contributing to a cleaner environment. |

| Reduced Waste Generation | Utilizing recycled aluminum conserves natural resources and reduces the amount of waste sent to landfills. |

| Conservation of Natural Resources | Recycling aluminum conserves finite resources and minimizes the demand for virgin materials. |

| Enhanced Sustainability | Overall, the use of recycled aluminum substructures contributes to a more sustainable approach, promoting a circular economy. |

Challenges and Future Trends

Recycled aluminum substructures offer significant environmental benefits, but their widespread adoption faces certain hurdles. Understanding these challenges and exploring potential solutions is crucial for realizing the full potential of this sustainable material. This section will examine current obstacles, future trends, and innovative approaches to propel the development and application of recycled aluminum substructures.

Current Challenges

Several factors currently hinder the broader use of recycled aluminum substructures. Cost competitiveness with virgin aluminum, consistency in material properties, and the availability of standardized manufacturing processes pose challenges. Meeting stringent design specifications for various applications and ensuring the longevity of the recycled material in different environments are also important considerations.

- Cost Competitiveness: Recycled aluminum often has a slightly higher initial cost compared to virgin aluminum. This difference stems from the energy required in the recycling process and the need for specialized processing. However, the cost gap is expected to narrow as recycling technologies improve and economies of scale emerge.

- Material Property Consistency: Variations in the quality and composition of recycled aluminum scrap can lead to inconsistencies in the resulting substructure’s mechanical properties, such as strength and ductility. This variability necessitates meticulous quality control measures throughout the manufacturing process.

- Standardized Manufacturing Processes: The lack of standardized manufacturing processes for recycled aluminum substructures creates difficulties in design, production, and quality assurance. Developing and implementing industry-wide standards is essential for wider adoption.

- Meeting Design Specifications: Recycled aluminum substructures need to meet the same stringent design specifications as those made from virgin aluminum. Ensuring consistent performance across various applications, including aerospace, automotive, and construction, is critical.

- Long-Term Durability: The long-term performance and durability of recycled aluminum substructures in different environments (e.g., corrosive marine environments, high-temperature applications) need to be rigorously tested and validated. Addressing potential degradation issues is key.

Potential Solutions

Several approaches can mitigate the identified challenges. Investments in advanced recycling technologies, the development of robust quality control protocols, and the creation of industry-wide standards can significantly improve the competitiveness and reliability of recycled aluminum substructures.

- Advanced Recycling Technologies: Investing in advanced technologies for aluminum recycling, such as advanced sorting and purification methods, can reduce the cost and increase the consistency of recycled aluminum, thus closing the cost gap with virgin aluminum. For example, hydrometallurgical methods can recover aluminum from complex waste streams more efficiently.

- Robust Quality Control Protocols: Implementing comprehensive quality control measures throughout the manufacturing process, including rigorous testing and analysis of recycled aluminum alloys, can ensure the consistent performance of the resulting substructures. Sophisticated material characterization techniques are vital.

- Industry-Wide Standards: Developing and enforcing industry-wide standards for recycled aluminum substructures will promote interoperability, facilitate design optimization, and ensure consistent quality across different manufacturers.

- Advanced Design Techniques: Using advanced design techniques, such as finite element analysis (FEA), can optimize the use of recycled aluminum, leading to lighter, stronger, and more efficient substructures. This includes understanding and accounting for the specific properties of recycled materials.

- Long-Term Durability Testing: Extensive long-term durability testing in relevant environments, followed by the development of appropriate corrosion protection strategies, can address concerns about the longevity of recycled aluminum substructures. This could involve incorporating specialized coatings or surface treatments.

Future Trends

The future of recycled aluminum substructures will be shaped by innovations in materials science, manufacturing processes, and design.

- Materials Science Advancements: Continued research into aluminum alloys specifically tailored for recycling can enhance the mechanical properties and corrosion resistance of recycled aluminum substructures, potentially reducing the need for additional treatments.

- Additive Manufacturing (3D Printing): 3D printing techniques will enable more complex and customized designs, which could lead to significant weight savings and enhanced functionality in recycled aluminum substructures. This will open up new possibilities for application in various industries.

- Integration of Recycled Materials in Composite Structures: The integration of recycled aluminum into composite structures is likely to gain traction, providing a lightweight and strong solution for various applications, like in automotive and aerospace industries.

Future Opportunities

The opportunities for innovation and technological advancements in recycled aluminum substructures are significant. The development of more cost-effective recycling processes, the exploration of new applications, and the increasing demand for sustainable solutions will fuel future growth.

| Challenges | Proposed Solutions |

|---|---|

| Cost competitiveness with virgin aluminum | Advanced recycling technologies, economies of scale |

| Material property consistency | Robust quality control protocols, advanced material characterization |

| Standardized manufacturing processes | Development and implementation of industry-wide standards |

| Meeting design specifications | Advanced design techniques, consideration of material properties |

| Long-term durability | Extensive long-term testing, corrosion protection strategies |

Technical Specifications and Standards

Recycled aluminum substructures, like their new counterparts, need to meet specific requirements to ensure quality, safety, and performance. These specifications and accompanying standards guarantee that the substructures function as intended and are suitable for their intended applications. Adhering to these standards is critical for ensuring consistency and preventing potential issues.

Key Technical Specifications

Technical specifications cover a wide range of aspects, from material composition and dimensions to strength and durability. These specifications are vital for ensuring the substructures can withstand the intended loads and environmental conditions. Compliance with these standards guarantees that the substructures meet predefined quality criteria.

Industry Standards

Various industry standards provide detailed guidelines for recycled aluminum substructures. These standards often specify requirements for material composition, manufacturing processes, testing procedures, and dimensional tolerances. Adherence to these standards fosters interoperability and reliability. Examples include standards related to structural integrity, such as those set by the American Institute of Steel Construction (AISC) or similar organizations for aluminum structures, along with specific standards for recycled materials.

Standards for recycled aluminum typically focus on the purity, particle size, and other attributes to ensure the quality and performance of the final product.

Importance of Adherence to Standards

Adhering to these standards is crucial for several reasons. Firstly, it ensures the structural integrity and safety of the substructure. Secondly, it facilitates interchangeability with other components and systems. Thirdly, it helps maintain consistency in the quality of the substructures. Finally, it promotes a standardized approach, which can lower production costs in the long run and minimize potential liabilities.

Impact of Non-Compliance

Non-compliance with technical specifications and industry standards can lead to serious consequences. These consequences range from design flaws and performance issues to safety hazards and legal repercussions. Failure to meet these standards could result in the substructure not meeting load requirements, potentially leading to structural failure. Non-compliance can also damage the reputation of the manufacturer and create liability issues.

Table of Key Technical Specifications and Standards

| Key Technical Specification | Corresponding Standard (Example) |

|---|---|

| Material Composition (Recycled Aluminum Alloy) | ASTM B221 (Aluminum and Aluminum Alloys) or specific standards for recycled aluminum alloys. |

| Dimensional Tolerances | ASME Y14.5 (Dimensioning and Tolerancing) |

| Tensile Strength | ASTM E8 (Tensile Testing) or similar standards specific to aluminum alloys |

| Yield Strength | ASTM E8 (Tensile Testing) or similar standards specific to aluminum alloys |

| Corrosion Resistance | ASTM B117 (Salt Spray Testing) or other relevant standards for corrosion resistance |

| Fatigue Resistance | ASTM E606 (Fatigue Testing of Metallic Materials) or equivalent standards |

Closing Summary

In conclusion, recycled aluminum substructures present a promising path towards a more sustainable future. Their environmental benefits, coupled with competitive cost analysis and adaptable design principles, position them for significant growth in various sectors. Further research and innovation will be crucial to address the remaining challenges and fully unlock the potential of this transformative material.

Answers to Common Questions

What are the different types of recycled aluminum used in substructures?

Various grades of recycled aluminum are used, each with specific properties. The type chosen depends on the intended application and the required strength characteristics. Some common types include scrap aluminum from manufacturing processes, construction demolition, and even automotive recycling.

What are the key environmental benefits of using recycled aluminum?

Recycling aluminum significantly reduces the energy required compared to producing it from raw materials. This translates to a lower carbon footprint and reduced reliance on finite natural resources. It also minimizes waste going to landfills.

What are some common applications for recycled aluminum substructures?

Recycled aluminum substructures are finding use in various industries, including construction, automotive, and aerospace. Their lightweight nature and high strength make them suitable for diverse applications where durability and sustainability are paramount.

How does the cost of recycled aluminum compare to virgin aluminum?

Generally, recycled aluminum is more cost-effective than virgin aluminum. However, the precise cost difference varies depending on factors like the grade of recycled aluminum and the current market prices.

What are the potential challenges associated with using recycled aluminum?

Challenges can include variations in material properties among recycled batches and potential quality control issues. Ensuring consistent performance across projects requires careful material selection and rigorous quality control processes.